Inlay - 16.5oz, 18gauze jersey fabric -

Inlay - 16.5oz, 18gauze jersey fabric -

16.5oz, 18gauze jersey fabric.

”Inlay" have become representative of Japan Blue Jeans' tops.

Inlay (knitting) is manufactured at a factory in Gifu.

For those of us who have long been involved in the denim industry, our encounter with inlay was full of new discoveries.

We will introduce our commitment to fabric production and its production background, which only a knitter's factory can offer.

What is "Inlay"?

Inlay means "inlaid" or "inserted".

This is a method of knitting by inserting yarns twisted by the force of air between the base knitting fabric.

The knitted fabric is similar to what is called "French terry" or "loop back", but the difference is that there is no binding yarns in the middle.

Therefore the inlay can have a firm and solid texture with little stretch while reducing their thickness.

It was about eight years ago that we requested this factory to manufacture our products.

As we were planning a new product, we were fascinated by a certain "inlay" fabric.

Features of that inlay is hard touch feeling and thickness.

And it has such a texture that has a nostalgic and soft texture somewhere.

However, we learned that the factory that manufactured it was already out of business, and we were looking for a factory that could reproduce the fabric and we reached our current factory.

Denim is "weaving" and Inlay is "knitting"

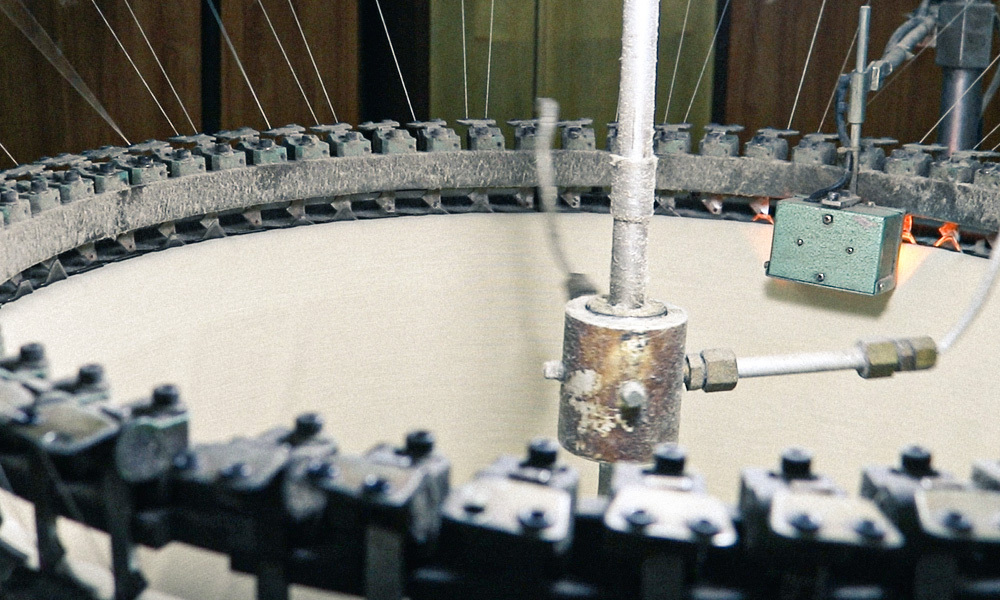

The first day we saw an inlay knitting machine, we were excited by the large circular machine.

The machine used to weave inlays is called a "sinker knitting machine", and thin metal plates called "sinker" role as a pressure (*The part held in the hand in the photo above).

The knitting machine in which this part is used is collectively called a sinker knitting machine in Japan.

To manage non-standard yarns.

Although we had expected this, the fabric we requested for this inlay was hard and thick, using a thicker than standard yarn, so it was not a simple task.

Knitting factories are prone to cotton dust environment.

The cotton dust could be a factor in yarn tangling and machine trouble, and the factory manager repeatedly said "we are not able to knit this" and we were kept refusing by him.

We wondered if this project itself was impossible....

On the other hand, we were still wanted to "make it happen somehow!", and were encouraged many times by the passion of the factory manager who repeatedly devised measures through trial and error "Next time, next time!" to our unreasonable requests.

The secret plans of the factory manager who is friendly and a little shy.

Gifu is hot in summer and cold in winter.

At this small factory, a sinker knitting machine from the 1980s is still in operation, and the factory manager makes detailed adjustments every day based on his long years of experience and know-how.

To create a hard texture that retains softness but also remains firm and heavy.

Through our interview, he told us about the two processes applied to JAPAN BLUE JEANS' inlay yarn.

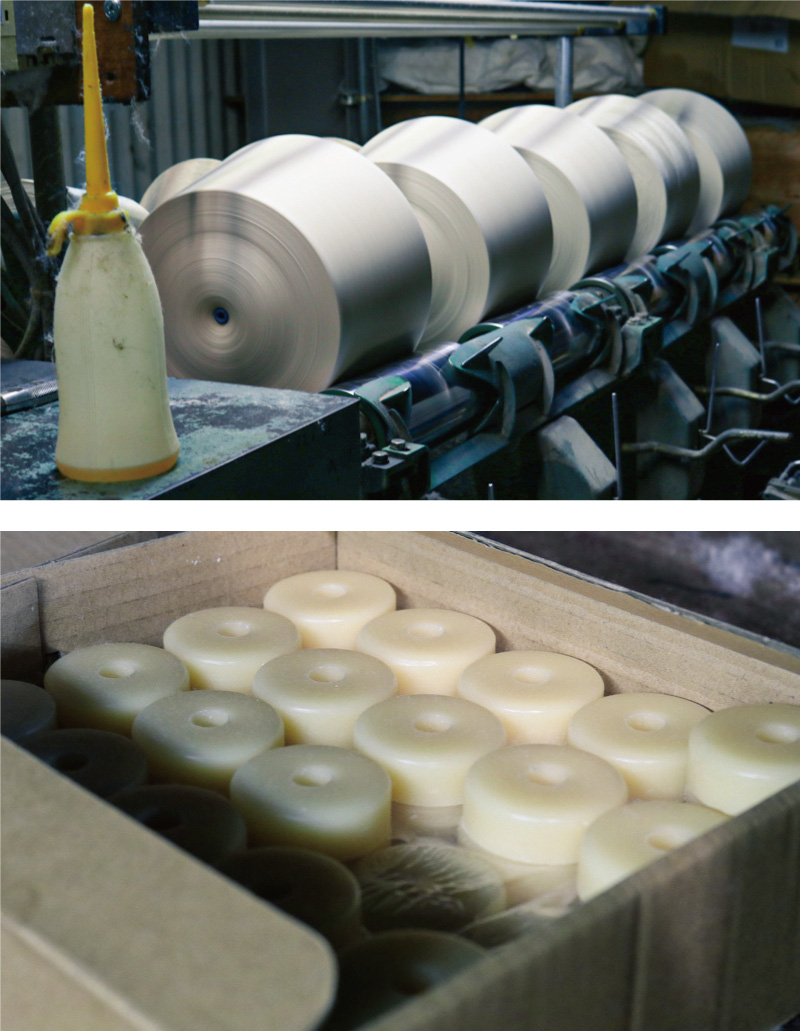

1. Steaming the yarn to soften and loosen it before knitting.

2. To reduce cotton dust by making the yarn firm and crisp by running it through silicon wax to make it more slippery.

If silicon wax is cheap, it tends to dissolve easily or slip and produce scraps, and it is necessary to use a reasonably priced wax to achieve firmness and texture.

Of course, there are other techniques and know-how involved, but these two secret measures have resulted in JAPAN BLUE JEANS' inlays that are firm, thick, and have a unique feel and comfort.

We are very attached to this inlay.

This "attachment" is due to our connection with a factory that reproduces our own particular style, which is based on a textile manufacturer.

Even though the region is different, the skill and passion for craftsmanship remain deep-rooted.

It is not efficient by any means, but we would like to convey the unique texture of this inlay.

The outer surface has a hard texture yet the inside has a comfortable feel.

The way it becomes softer and softer as you wear it is just like our jeans.

< Aging Sample >