Japanese denim is the best in the world!?

Japanese denim is the best in the world!?

"Japanese denim is the best in the world!"

We often have these kinds of compliments thankfully.

However what makes it the best in the world?

Kishimoto, JBJ's director, thinks the reason of it in order to be the No.1 position.

16.5oz Cote d'Ivoire cotton selvedge denim

He thinks that there is a difference about the goal between denim factories in Japan and overseas.

〇 Overseas

・Efficiently, cheaply, and large quantity.

・In order to increase production efficiency, they use the latest machines through integrated production.

〇 Japan

・Manufacturing begins with how to make denim with good color fading and interesting fabrics.

・Efficiency is inferior to that of overseas due to the specialization of factories.

・There are many unique developments that seem to be useless.

There is no answer which is better because the purposes are different, but it seems that other countries are better in terms of business...lol

All denim fabrics which used in JAPAN BLUE JEANS can be produced only in Japan.

Among them, 16.5oz Cote d'Ivoire cotton selvedge denim is quite special.

It is used in JBJ's standard jeans (CIRCLE) and denim jackets.

"Let's make the denim fabric that has great aging!"

That is the start of the development.

To make great aging, the unevenness of yarn (thin and thick parts) is necessary.

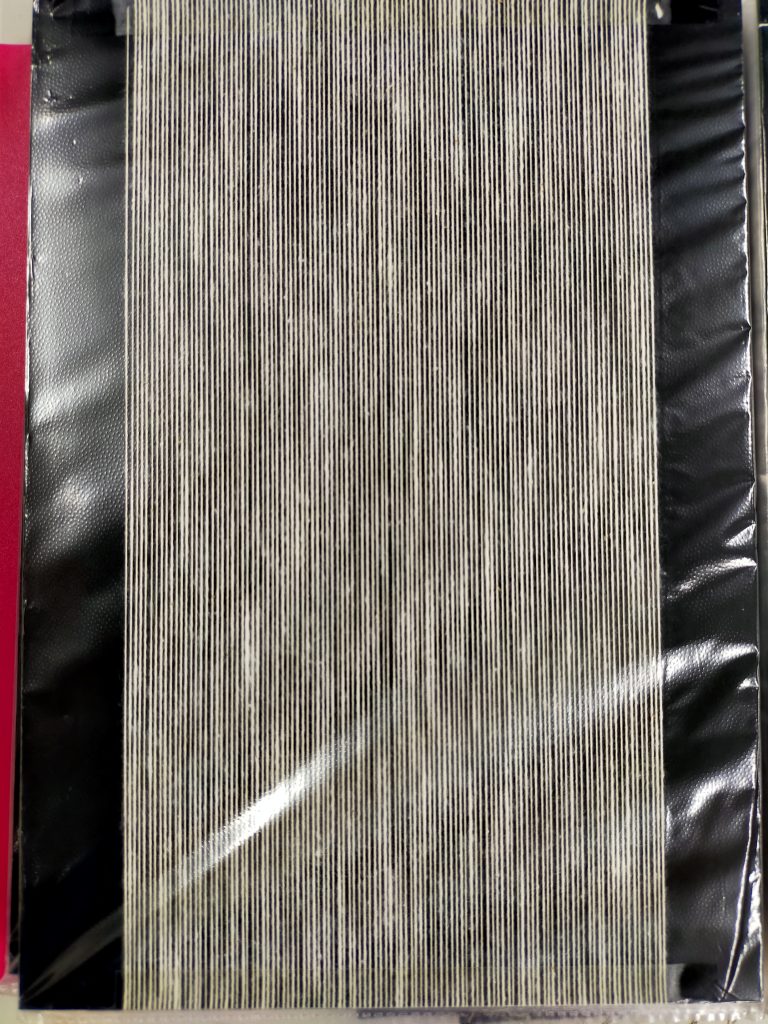

This is called ”Itamaki” - we use this to check the unevenness of yarn.

However, if we make the unevenness more (a larger difference between thick and thin), the yarn will break more easily.

Making thread that is easy to break means...

・The B product rate increases in spinning.

・If the yarn is broken in dyeing process, it will cause a lot of loss, such as stopping the machine or throwing away the yarn.

・Even weaving is quite inefficient.

Integrated factory tends to "make the unevenness of the yarn less and increase productivity", but in Japan, the higher the wall, the more people want to climb it.

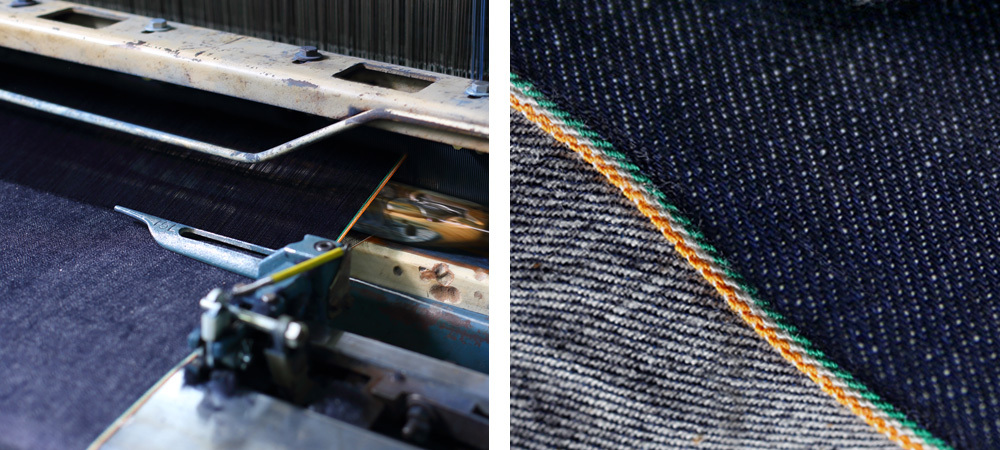

The latest computer-controlled machines are more efficient.

Old machines remaining in Japan are not as good as the new ones, but we can do more things compare to it due to less limitation, and also the craftsperson's experience and motivation can help solve more problems.

The factory manager's footing when the loom is not working well.

Kishimoto thinks that these create denim fabric that you've never seen before, and are the reasons why "Japanese denim is the best in the world!".

We are sure that interesting fabrics are also made overseas and there are many technologies and ideas that cannot be imitated at all,

So....We think "both are the best!"

By the way, do you know JAPAN BLUE JEANS is the only brand that makes jeans using 100% Côte d'Ivoire cotton?

If you make yarn with only a single type of cotton, there is a difference in the quality of the cotton depending on the year of harvest, which can lead to inefficiency.

But... We've been getting over it with experience and adjustment!

Click here to read more about Côte d'Ivoire cotton.

Shop Côte d'Ivoire cotton denim items.